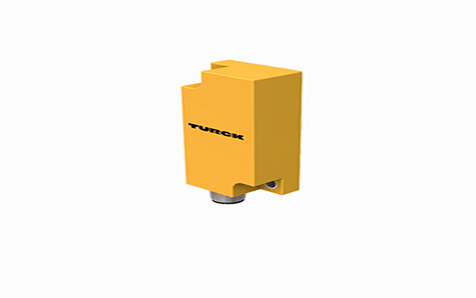

Inductive

Inductive sensors detect metal objects contactless and wear-free. For this, they use a high-frequency electromagnetic AC field that interacts with the target. Their strengths are the enormous durability, reliability, high switching frequencies and a long service life. Through a unique coil concept the uprox sensors offer the highest switching distance, factor 1 for all metals and, right from the start, the highest operational safety through simple and safe installation.